Description

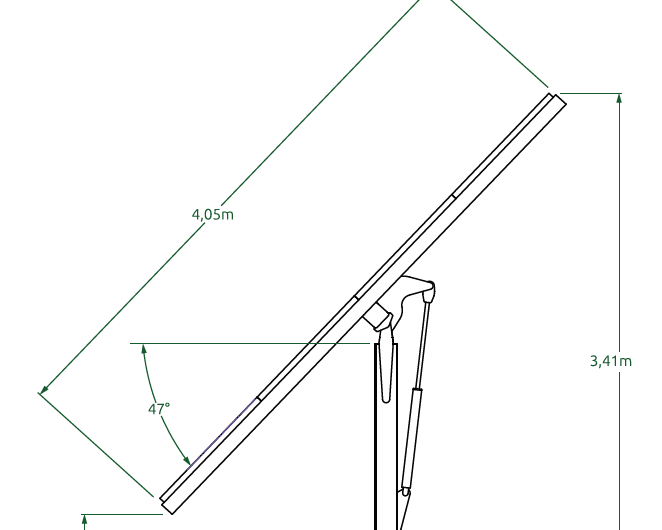

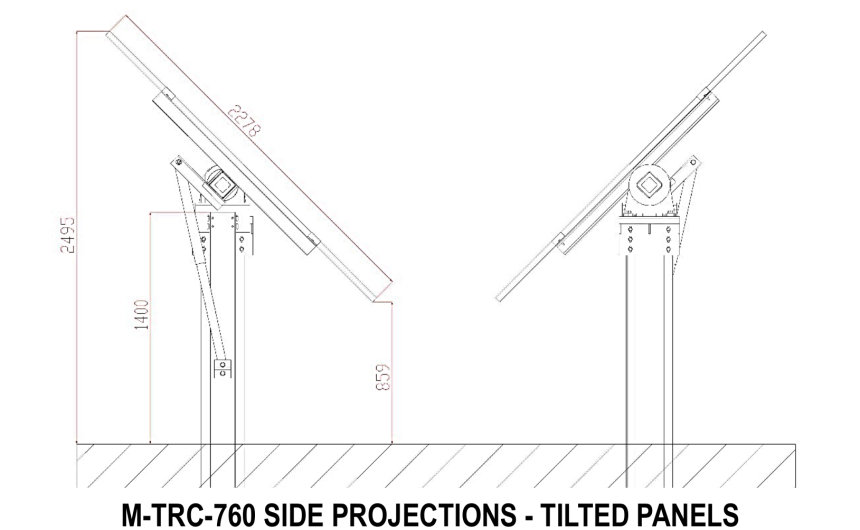

Metaloumin manufactures horizontal single-axis hydraulic trackers for photovoltaic installations, fully adaptable to project needs. Inventive design, makes horizontal single-axis hydraulic trackers the optimal solution for any type of ground, of any shape or dimension, regardless of slope, as well as horizontal surfaces, applicable to installation setups of any orientation.

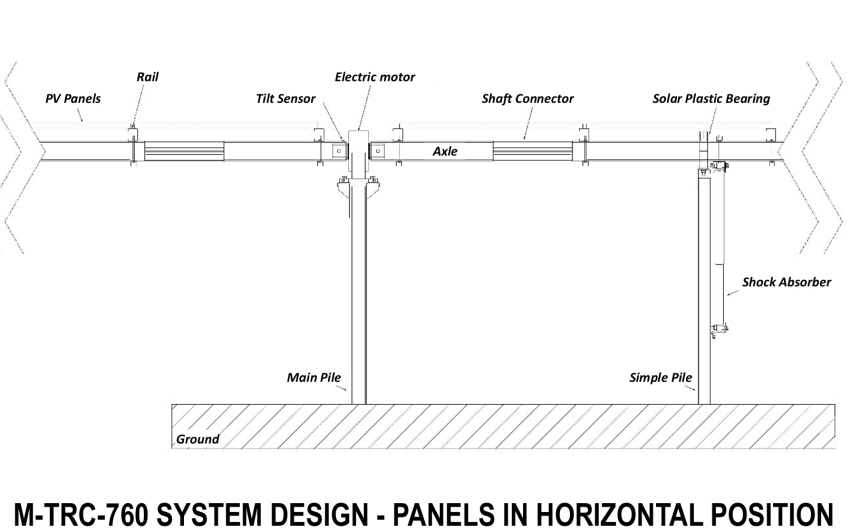

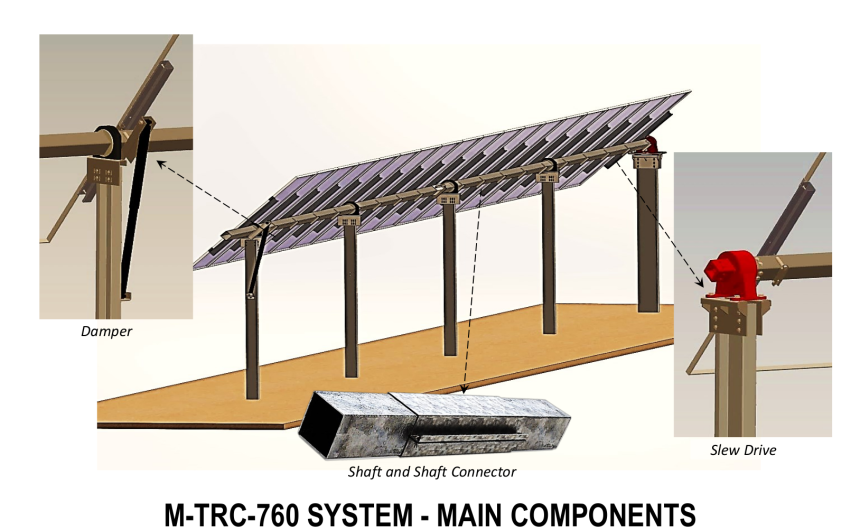

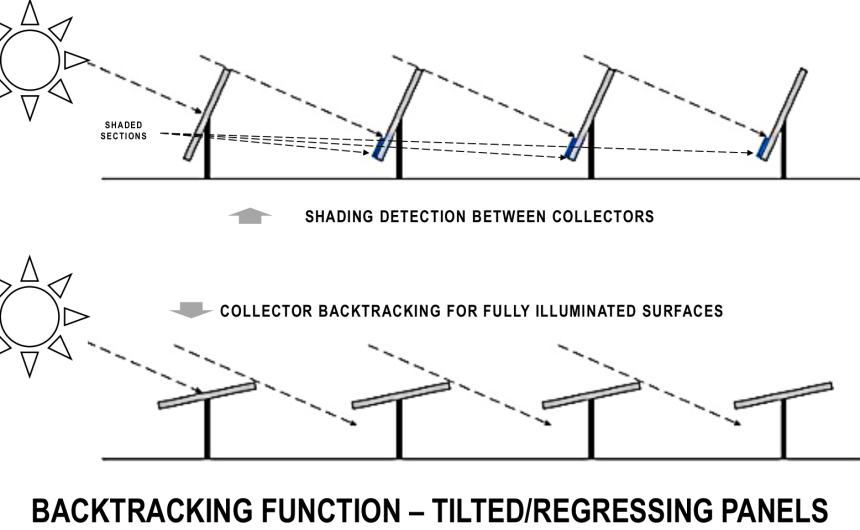

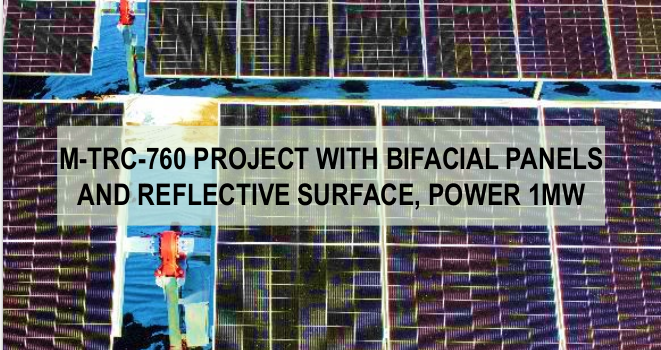

Use of Metatracker, compared to equivalent fixed underside systems, can increase energy produced by up to 25%. The horizontal single-axis tracker system of Metaloumin is one of the most advanced in the market. Main features are the drive system consisting of hydraulic pistons offering added reliability compared to electric motors, reduced number of piles for quick installation, independent structural motion for maximum efficiency (i.e., backtracking function), as well as specialized provisions in bifacial collector applications, with flip-surface zero shading.

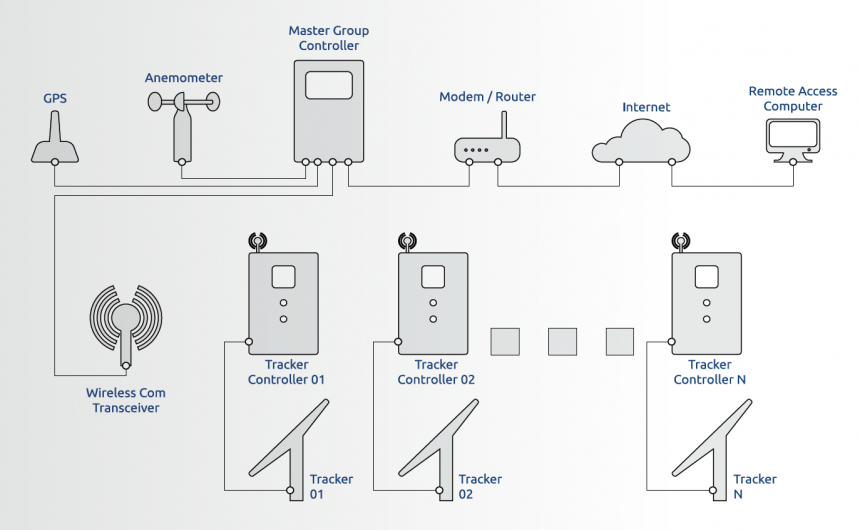

Metaloumin single-axis trackers feature AC/DC power supply (self-supply on request, using a small collector added to the main construction), with a choice for remote system operation and monitoring. Dedicated Metatracker engineering and design, prioritize coverage of all our customers’ needs and preferences, adapting to particular customer and location requirements, adhering to local regulations. The Metatracker support system is made of hot-dip galvanized steel, while the joints are a combination of stainless steel and brass, all made suitable for adverse weather conditions, able to operate in snow and desert environments, and under any combination of dust and moisture.

By choosing Metatracker, you opt for a guaranteed Greek product, made by a manufacturing company of more than twelve years of experience in the PV collector support systems market. Metaloumin always stands by its clients for any guidance and assistance required, during the life of the project.

Advantages

- Fully autonomous system

- ROI (return on investment) maximization

- Multiple foundation / panel layout options

- Suitable for all surface / soil types

- State-of-the-art software with multiple user levels

- Optimal panel position throughout the day

- Wireless control technology – Minimal wiring

- Remote control via Internet

- Early warning system

- Minimum maintenance costs

- Increased security and reliability

- Operation under adverse conditions